|

|

Paratus Industries designs and manufactures rolls for many different applications. These designs include single shell, double shell, solid, coated and electrically heated rolls. With maximum roll building capacities to 36 inch diameter and 200 inch face capacities, we can meet the needs of most roll applications.

Common roll applications:

- Calender Rolls

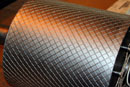

- Embossing Rolls

- Dryer Rolls and Drums

- Heating Rolls

- Chilled Rolls

- Idler Rolls

Roll Designs:

- Single shell for heating or cooling

- Double shell for heating or cooling

- Solid rolls

- Live or dead shaft rolls

- Rubber, composite or specialty coated

- Direct electric roll heating

Direct Electric Heated Rolls:

We also design and build a line of electrically heated calendering and embossing rolls. Rotary joints often leak on oil heated rolls and oil heating units take up precious floor space. These electric rolls eliminate the need for messy and troublesome oil heated rolls and heating units. Additionally, the direct electric heated rolls provide a much safer work environment. Direct electrically heated rolls can be supplied to 36 inches in diameter and 76 inches in face. Our direct electric heated rolls have a Δ T comparable to double shell oil heated rolls with much quicker response time.

Electrically heated roll advantages:

- Δ T comparable to double shell oil heated rolls

- Cleaner

- Require less floor space

- Safer

- More economical and efficient

Call us today for an analysis of your process specifications to see if you troublesome oil heated rolls can be replaced with Paratus Industries’ Direct Electric Heated Rolls.

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|